Cadmium Sulfide Nanoparticles

Cadmium sulfide nanoparticles and their quantum dot version are of a significant interest due to their semiconducting and luminescent properties, especially their controllable emission bands, continuous excitation and the ease of functionalization. Cadmium sulfide (CDS) is particularly used in devices with optoelectronic property and is known to be a direct band gap material at room temperature. Cadmium sulfide has attracted a lot of attention due to an extensive range of applications and unique properties. In fact, cadmium sulfide among the most widely studied semiconducting material with unique chemical and optical characteristics because of its quantum size effect. Particularly, cadmium sulfide has been shown to be a highly qualified photosensitive material and its perfect compatibility with organic semiconductors makes it a potential agent as an electron acceptor with an application in solar cells1.

Generally, cadmium sulfide is a yellow inorganic compound that occurs naturally as two distinct crystal lattices in the form of rare minerals and du to structural similarities, it is found in zinc ores as impurities as cadmium’s main economic source. With regard to the technical fact in nanotechnology, matter and mostly solids adopts specific, intensified, improved and novel properties when they fall into nano scale. In the case of semiconductor nanomaterials, the fundamental point to take into consideration is the development of efficient and reliable synthetic methods in order to obtain particles with appropriate size and morphology.

Physical and Chemical Properties of Cadmium Sulfide Nanoparticles

Similar to zinc sulfide, cadmium sulfide occurs in two crystalline forms with the hexagonal wurtzite as the most stable structure and the cubic zinc blende. Cadmium and sulfur atoms in these two crystalline forms adopt four coordination states. Cadmium sulfide is considered as a direct band gap semiconductor with its color being originated from visibility to electromagnetic radiation. Its conductivity increases with its irradiated and when it’s coupled with semiconductors of p-type, it can form the core component of solar or photovoltaic cells. It should be mentioned that CDS/Cu2S is among the first efficient solar cells introduced back in 1954. Cadmium sulfide adopts luminescent quality when it’s doped with Al3+ or Cu+ under electron beam excitation with applications in phosphorescence analyses. When cadmium sulfide is formed like a thin film, it adopts piezoelectric behavior to be used as transducers and can operate at Giga Hertz (GHz) region.

Synthesis and Preparation of Cadmium Sulfide Nanoparticles

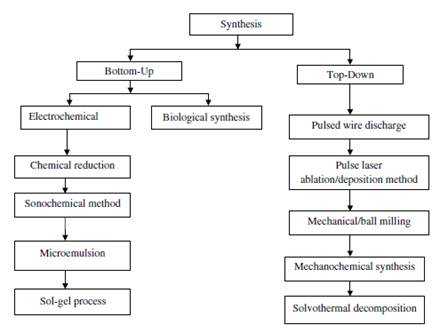

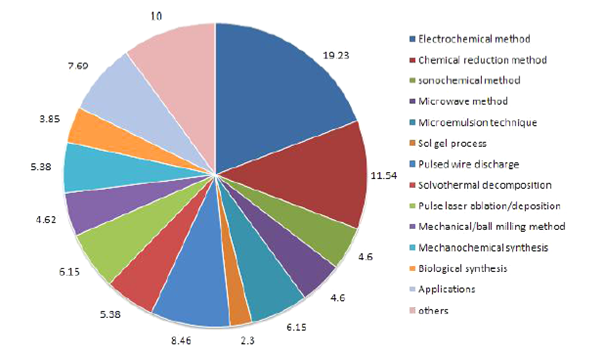

Cadmium sulfide nanoparticle have been prepared based on methods such as Microwave-assisted solution precipitation synthesis, Chemical Vapor Deposition, solution precipitation, DC Electrochemical Deposition, gas phase reaction with hydrogen sulfide (H2S) or sulfur vapor, solvothermal and hydrothermal, and thermolysis process so far. Microwave assisted heating method has been used as an advantageous method with short reaction time and high energy efficiency as well as the possibility of inducing particles with smaller size, higher purity and narrower size distribution due to homogenous heating by microwave irradiation 1. On the contrary for solar cells, it is essential to investigate the physical and chemical properties as well as photovoltaic performance that are affected by preparation conditions of CDS synthesis. For an application in solar cells, cadmium sulfide nanoparticles are synthesized taking the advantage of microwave radiation and the solution precipitation method using thiourea (TU) and thioacetamide (TA) as the sources of sulfur. A solution containing cadmium chloride (CdCl2), sodium citrate (HOC(COONa)(CH2COONa)2) and KOH are prepared and the pH is adjusted to be around 7. The solution is heated up by microwave radiation up to 150°C and maximum 30 minutes until it changes to yellow. The resulting CDS should be washed and dried at room temperature 1.

Recently, a novel biological using capping biomolecules method has also been suggested to synthesize cadmium sulfide nanoparticles. Some studies have reported microbial synthesis of CDS nanoparticles using the E-Coli based on the concept that nanoscale crystals synthesis relies on cell’s growth phase. In a different biosynthetic method, bacterial protein has been employed to serve in the synthesis process and particle formation. Nanosized cadmium sulfide crystals synthesis has been prepared through genetic engineering using genes that are responsible to bind CDS to peptides. In general, biomolecules and microorganisms sustain a significant number of nucleation centers to control particle size, crystallinity and morphology of nanomaterials and make it possible to achieve highly stable and dispersed nanoparticles 2. Particularly in a biological method, the biosynthesis of CDS nanoparticles involves the use of microbial cells obtained from a logarithmic phase being in the mature and high dividing stage of their bacterial life cycle. The bacterial cells are centrifuged and washed in phosphate-buffered saline (PBS, pH 7.4) to ensure the removal of the bacterial culture media. CdCl2solution is added to buffer containing the bacteria and incubated for 12 hours at 37°C to obtain the desired cadmium sulfide nanoparticles 2.

In a methods called thermal decomposition, cadmium sulfide nanoparticles are synthesized by a novel Cd-octonate complex. In this order, CDS nanoparticles are synthesized under argon atmosphere, an amount of sulfur is added to Cd-octonate complex and heated at 170 °C 2 hours with a color change from green to black. The resulting solution is left to cool down to room temperature and the nanoparticles are separated and washed in ethanol and dried 3.

Applications of Cadmium Sulfide Nanoparticles

Cadmium sulfide nanoparticles are known for their extensive applications dual semiconducting and luminescence properties and show a great promise in medical imaging and treatment of disease. CDS nanoparticles have potential applications in laser light-emitting diodes, thin film transistors, electronic and non-linear optical optoelectronic devices, single-electron transistors, photo catalysis photo-electrochemical cells, solar cells, in electroluminescence analysis thin films and solid state lasers. In thin films, cadmium sulfide is combined with interactive layers for applications in some specific solar cells. They are also among the first semiconductor materials used widely in thin film transistors. Cadmium sulfide thin films exhibit piezoelectric behavior and are employed as transducers that can operate at Giga Hertz region of electromagnetic radiation. Nanoscale cadmium sulfide has shown to have a net cooling which originates from the annihilation of photons during anti-stock luminescence at wavelengths as small as 510 nm. Therefore, a maximum decline in temperature is recorded when nanoscale cadmium sulfide particles are pumped with a laser that functions at wavelengths like 514 and 532 nm.

Conclusion

The dual property and extensive applications have made cadmium sulfide nanoparticles as qualified nanomaterials to attract a lot of attention in industries, medicine and science. In addition to common physical and chemical methods, the synthesis methods fit in the standards of green chemistry due to the use of biomolecules like bacteria with applications in medicine.

References

1. Martínez-Alonso, C., Rodríguez-Castañeda, C. A., Moreno-Romero, P., Coria-Monroy, S. & Hu, H. Cadmium sulfide nanoparticles synthesized by microwave heating for hybrid solar cell applications. Int. J. Photoenergy 2014, 10–12 (2014).

2. Sankhla, A. et al. Biosynthesis and characterization of cadmium sulfide nanoparticles – An emphasis of zeta potential behavior due to capping. Mater. Chem. Phys. 170, 44–51 (2016).

3. Seyghalkar, H., Sabet, M. & Salavati-Niasari, M. Synthesis and Characterization of Cadmium Sulfide Nanoparticles via a Simple Thermal Decompose Method. High Temp. Mater. Process. 35, 1013–1016 (2016).

Hydroxyapatite Powder

Hydroxyapatite powder also called HA powder is a mineral present in either solid or crystalline form which is then converted into the powdered form. It is based on the presence of calcium, hydroxyl ions and phosphorus in different ratios. It is synthesized chemically in various forms having a balanced chemical equation with appropriate ratios. It has two biological functions too, mantis shrimp and humans/mammals/primates. It has several uses as well in the field of cosmetics, supplements, medical and archeology. With the world pacing at such a great rate, HA powder has proved to be beneficial in several ways. Though there are still some manufacturers who are claiming this mineral to be a misfit but on the other hand, it has multiple supporters too so that is why it is rightly believed that benefits and misfits go hand in hand and it is true in plenty of ways too because we have to be careful as to what product or use of HA powder will prove to be beneficial or harmful for us.

Introduction

Hydroxyapatite which is also known as hydroxylapatite (HA) is a form of a mineral calcium apatite which occurs naturally, the formula of which is Ca5(PO4)3(OH). It is therefore known that the mineral hydroxyapatite is a crystalline formed cell and has two separate structures. Hydroxyapatite is one of the members of the apatite group, which is a complex one. The hydroxyl ions can be alternated by carbonate, chloride or fluoride. Upon heating, it is crystallized and is present in the crystalline form which can then be converted into the powdered form by crushing the crystals of it that is why the pure form of it is in white colour. Although the ones which occur naturally might be present in other colours too, that is brown, yellow or green. A bone mineral which is present in a normal human bone is an altered form of the hydroxyapatite because fifty per cent of it by volume and seventy percent of it by weight is actually the bone mineral comprised of hydroxyapatite. The minute structures of hydroxyapatite are also found in the pineal gland, brain sand and a few other structures of the human body. These are the tiny calcifications of the human body.

Hydroxyapatite powder can be chemically synthesized in multiple different ways. Calcium, phosphorus and hydroxyl ions are the main components of a hydroxyapatite powder. They can be altered in various ways to bring out various shapes and forms of the powder, but the main formula and equation that formulates the process remain the same which are mentioned below respectfully.

It can be formed in solid-state too which later on is converted into the crystalline form and from that is converted into the powdered form to perform various functions for different purposes.

Properties of Hydroxyapatite powder

The most prominent property of hydroxyapatite powder is the level of its stability at the time of comparison with the other calcium phosphates. However, HA powder is believed to be that calcium phosphate compound which is the most stable under the influence of physical conditions such as the composition of body fluids, pH and temperature. Following are the exceptional chemical properties of HA powder:

Structure of Hydroxyapatite

Biocompatibility:

One of the excellent property of HA powder is biocompatibility. HA powder enhances the biocompatibility of all the products it is used in.

Bioactivity:

Another good property of HA powder is bioactivity. All the products or minerals which have HA powder extraction in them speeds up the bioactivity of those products or minerals.

Osteoconductivity:

Osteoconductivity too is one of the greatest properties of HA powder. As HA powder can either be transparent or opaque, so osteoconductivity is exceptionally enhanced in it.

Non-toxicity and non-inflammatory nature:

HA powder possesses the non-toxic and non-inflammatory nature that is why it can be used for various purposes as it has no harmful, toxic or inflammatory effects on any of the things it is mixed with.

Following are the physical properties of the HA powder:

1)Like all the other ceramics, HA is also very brittle.

2)The usual colours of HA powder are green, grey, red, brown, violet or colourless, but the colour of it depends upon the type of apatite.

3)It can be transparent or opaque.

4)It gets degraded in the solution of 2.0 pH.

Uses of hydroxyapatite powder

Hydroxyapatite powder is used in various fields for various purposes which are mentioned below as it is one of the most preferred minerals in the industry because of its remarkable benefits.

Uses of hydroxyapatite powder in Cosmetics

The products such as Johnson’s Aloe and Vitamin E powder are the ones which have HA powder in them. It is to be notified that these make the products help in either moisturizing the skin or softening the skin of the babies. It is also present in the makeup kits as their initial purpose is to provide moisture and softness to the skin. A few rare cases of HA powder being used in the shampoos too came out as to give protection to the dry and dull hair. It proved beneficial in the hair products too. These products are very reliable and are being sold and purchased at a very great rate in the market as they are extremely beneficial, and HA products are one of the main contents that make these products beneficial.

Uses of hydroxyapatite powder in Medical:

In the field of medical, HA powder is drastically used for unique bodily implantations like hip replacements, dental implants and bone conduction implants. A very fine coating of HA is done on these implants for the protection because this powder contains calcium and phosphorus. Even though, science is making progress in enhancing the credibility of the structure of the bones via replacement because these are very much needed for the proper functioning of a normal human body and if these will be missed out from the implants then there are more chances of the implants being unsuccessful.

Use of hydroxyapatite powder in supplements:

Hydroxyapatite powder is also present in another form that is the microcrystalline form, and this form of hydroxyapatite is very much known as a supplement that has a very high rate of absorbing as compared to calcium and is retailed as a bone-building mineral in the powdered form. It is mainly the supplement for calcium and has been derived from the bovine bone. Along with that, there are certain, and countless companies proclaim this that the HA powder used in the supplements is corrupted by the usage of heavy metals as its effective causes have not proved to be well in the field.

Use of hydroxyapatite powder in archaeology:

Hydroxyapatite powder is also being used in the field of archeology for the reconstruction of the migrants, diets and climatic changes of the human and animal remains. Bone and teeth in their mineral forms play the role of reservoirs of the trace elements, which also include carbon, oxygen and strontium. The hydroxyapatite powder is constructively used for the indication of the diet as in which state it is present, the habits which a human or animal adopt according to the geographical regions or origins and abruptly for that reconsolidation of the previous temperatures and the shifts of the climatic changes.

Use of hydroxyapatite powder in chromatography:

Hydroxyapatite powder is also being used in the process of chromatography. It is one of the very complex processes and is often also known as mixed mode. It basically represents the attraction and reaction of positive and negative ions which are then converted to ions. For the purpose of purification, HA chromatography’s efficacy cannot be predicted on the basis of physical and chemical properties it holds. For the purpose of elution, the buffers having a high quantity of phosphate or the neutral salt are most preferably used.

Use of hydroxyapatite powder in defluoridation:

Hydroxyapatite powder works as an excellent adsorptive mineral to complete the defluoridation of normal drinking water. This is due to the reason that HA powder can form fluorapatite in a process following three steps only. The mineral HA powder helps in the removal of fluoride ions from the water, and it then replaces those fluoride ions with the hydroxyl ions which actually makes fluorapatite which is incredibly useful in the purification of the contaminated water.

Use of hydroxyapatite powder in Mammals/Humans/Primates:

In mammals, humans or primates the hydroxyapatite is present at two different places. One is bone, and the other is teeth.

In bone, the matrix of collagen is sixty-five to seventy percent of the mass which is basically hydroxyapatite. In teeth, the matrix of dentin and enamel are seventy to eighty percent of the mass which is basically hydroxyapatite

All the studies show that the harmful effects associated with the usage of HA powder in all the different fields are very less and are almost unlikely to be recorded. Along with that, the studies also show briefly that the usage of HA powder that is the calcium phosphate nanoparticles are considered very safe for humans. Besides being safe, these products bring ease and efficacy too in the lives of humans so the usage of this mineral should be continued and various other ways should be explored in which humans can make it more beneficial for them.

Conclusion

In conclusion, Hydroxyapatite powder is a very complex and beneficial mineral found from this planet Earth. All the processes and procedures that are carried out in order to bring it out in its most useful forms are complicated in their own sense and require a lot of practice. Once it is presented in its purified and useful forms, it can be served for various helpful purposes, and in almost all sorts of fields, it has its own benefits. Off course there are conceptions like any other thing about HA powder too that it causes some harmful effects as well which are acceptable, but if we look at the brighter side, then we will see how it is so much more beneficial for us. It protects our bones and teeth so impeccably that it is the greatest example of its benefits itself.

References

https://www.sciencedirect.com/science/article/pii/…

https://www.medicinenet.com/script/main/art.asp?ar…

https://www.sciencedirect.com/topics/materials-sci…

https://www.fluidinova.com/hydroxyapatite-properti…

Antimony Tin Oxide Nanoparticles

Antimony doped tin oxide (ATO) nanoparticles have been proven to exhibit special optical property and excellent electrical conductivity to be used as thin film electrodes. Studies have shown that antimony doped tin oxide possesses a high n-type electric performance and employed in the form of the traditionally produced aerogel thin films for the purpose of collecting electrons in solar cells. Introducing antimony to the tin oxide structure can significantly increase the electron conductivity making it an excellent conductive material. Antimony tin oxide is transparent in the entire region of visible electromagnetic light, whereas it reflects the infra-red light. Generally, majority of the research projects concerning ATO have concentrated on the thin films of antimony doped tin oxide no matter they are made of nanoparticles or from particular precursors directly.

Physical and Chemical Properties of Antimony Tin Oxide Nanoparticles

ATO nanoparticles have attracted significant attention due to their well-known infrared light insulation quality, electrically conducting oxide and optical transparency. Antimony as the n-type dopant of tin oxide (SnO2) modifies the band structure of the tin oxide. Extra electron donation to the conduction band upon a cation substitutional replacement is carried on via a dopant as an impurity. The band structure of antimony doped tin oxide shows analytical data of Sb-5s-like band in the tin oxide’s band gap by a characteristic free electron at the G point. Additionally, it is elicited that this band gap is basically a half filled metallic ion with extra thermal excitation into bands similar to those of tin capable of increasing the conductivity 1. Antimony, which is the doped agent in antimony tin oxide has two ionic states based on its two valence electrons as Sb3+ and Sb5+ with a feasible switch Sb3+↔Sb5+ regarded as the redox enzymes catalytic cycle analogue in which the metal ions serve as cofactors in order to promote the possible reversing redox reactions against intracellular oxidizing agents.

Generally, transparent conducting oxides (TCOs) like antimony tin oxide and its nanoscale crystals combine transparency quality in the visible range of electromagnetic wave with high electrical conductivity making them considerable materials for several optoelectrochemcial applications. TCOs like antimony tin oxide nanoparticles are produced predominantly and extensively as thin layers and coatings. However, there has been a fast-growing trend and interest on obtaining nanosized crystals as small as possible in order to take the advantages of nanoparticles novel and improved properties that add to the bulky mother materials. The colloidal dispersion of antimony tin oxide nanoparticles are of a great interest for wet chemical deposition purposes. As the chemical and physical properties of materials like ATO nanoparticles directly depends of the size and morphology, synthesis of this class of agents is of a significant step for humidity sensing applications.

Synthesis and Preparation of Antimony Tin Oxide Nanoparticle

Considering the predominant applications of antimony tin oxide nanoparticles, numerous methods and techniques have been introduced to obtain them. Basically, it has to be taken into consideration that the properties of ATO is influenced by the synthesis and preparation process. The goal is always to obtain crystals with controlled size and an appropriate monodispersity so that high performance material is achieved. On the contrary, it is still challenging to synthesize antimony tin oxide nanoparticles combining all the required standards and determining factors like adequate conductivity, desirable particle size crystallinity, narrow particle size distribution and favorable dispersibility in a particular solvent. The most common and known methods include simple thermal evaporation, microemulsions, sol-gel, hydrothermal methods, co precipitation, mechanochemical, laser ablation, screen printing, combustion route, microwave assisted synthesis, thermal decomposition, hot injection and DC arc plasma jet synthesis.

In a synthesis procedure based chemical precipitation method, a solution of hydrochloric acid (HCl) is prepared and a mixture of SnCl2.H2O and SbCl2 with the ratio of 1:4 is added to acid solution with a consecutive dropwise addition of ammonium hydroxide to them. In the next step, an amount of polyethylene glycol as a capping agent is added to the mixture while vigorous magnetic stirring for around 24 hours until all the ingredients engage in a complete reaction. The resulting crystals are dried at 80°C for 8 hours and calcined at 400°C 2.

In a different method, the synthesis of antimony tin oxide nanoparticles is done via dissolving granulated tin (Sn) in nitric acid (HNO3). Separately, Antimony trioxide (Sb2O3) is dissolved in melted citric acid and is added to the previous solution and stirred for 3 hours at room temperature. After that, antimony hydroxide is added to the solution in order to process the precipitation of Sb3+ and Sn4+ metal ions and the pH of the solution is adjusted at 7. The hydroxide precipitate is washed in double distilled water until the color of the samples turn yellow. The resulting precipitates are dried at 100°C for 4 hours and calcined at 600°C for 2 hours in a muffle furnace essential to ensure the particles conductive property 3. A number of studies has focused on the assembly of antimony tin oxide nanoparticles into aerogels as big as a few centimeters with increasing applications as catalysis, photo catalysis and ferroelectric agents with promising properties like high porosity, high surface area to low density magnetic and optical quality. The assembly procedure is carried out by microwave heating and the assistance of non-aqueous sol gel reaction of antimony acetate Sb(CH3COO)3 with tin chloride (SnCl2) in the solvent made by mixing benzyl alcohol and toluene. The resulting mixture is heated up to 150°C for 9 minutes to obtain a brown precipitate 4.

Applications of Antimony Tin Oxide Nanoparticle

Referring to the unique electrical and conductive properties, antimony tin oxide (ATO) nanoparticles have been used extensively as transparent electrodes and thin films, support material for electro catalysis, energy storage devices, gas sensors and photoelectrocatalysis. It has been employed as a supporting agent in composite materials, radioactive waste management and optoelectronics. The antimony doped tin oxide nanoparticles have found broad applications in solar cells and heat reflection coatings too. Since ATO nanoparticles are transparent in visible region, they can be used as heat mirrors and transparent electrodes as well.

Conclusion

Antimony tin oxide nanoparticles quality as a transparent agent with favorable electrical conductivity has made it interesting nanoscale crystals in thin film electrode fabrication. In fact, most of the research has focused on optimizing the synthetic methods with applications in thin films production. The electron collecting quality of ATO nanoparticles has been drawing attention to their use in developing efficient solar cells.

References

1. Krishnakumar, T. et al. Structural, optical and electrical characterization of antimony-substituted tin oxide nanoparticles. J. Phys. Chem. Solids 70, 993–999 (2009).

2. Yadav, B. C., Singh, R., Singh, S., Kumar, R. & Srivastava, R. Nanostructured antimony tin oxide synthesized via chemical precipitation method : its characterization and application in humidity sensing. 1–16.

3. Zhang, J. & Gao, L. Synthesis and characterization of antimony-doped tin oxide (ATO) nanoparticles. Inorg. Chem. Commun. 7, 91–93 (2004).

4. Rechberger, F., Ilari, G. & Niederberger, M. Assembly of antimony doped tin oxide nanocrystals into conducting macroscopic aerogel monoliths. Chem. Commun. 50, 13138–13141 (2014).

C60 Fullerenes

After quite a few years since their discovery, fullerenes are now a well-established subject of research in many areas of chemistry and materials science. Years of studies have made researchers aware of both potentials and limitations of this class of compounds. Fullerene science plays a noticeable role in fields, such as Nanotechnology, Supramolecular Chemistry and Materials Chemistry. One of the most promising territories of investigation includes the modification of the fullerene cage to improve and/ or enhance its qualities for various applicative purposes since fullerenes possess unusual magnetic, optical, photophysical, electrochemical, semiconducting and superconducting properties. A new research field has aroused based on the functionalization and study of new fullerene types in recent years, which intends to benefit from the properties of these carbon hollow clusters in different technological fields. The high number of functionalization probabilities combined with the rich supramolecular chemistry of fullerenes provides the production of multiple derivatives of fullerenes with a wide diversity of architectures and these are continuously discovered as novel materials.

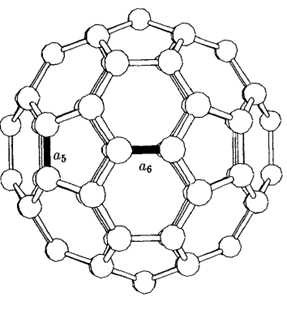

C60 fullerene (also called as Buckminsterfullerene) is a type of fullerene with the formula C60. It has a cage-like fused-ring that reminds of a soccer ball, and it is made of twenty hexagons and twelve pentagons, with a carbon atom which has one π bond and two σ bonds at each corner of the shape to create a universal vertex.

![Stereographic projection of C60 fullerene[1]. (Note: To visualize the 3D image, the picture must be held about 15 cm from the eyes and the eyes must focus at infinity). Stereographic projection of C60 fullerene[1]. (Note: To visualize the 3D image, the picture must be held about 15 cm from the eyes and the eyes must focus at infinity).](https://nanografi.com/product_images/uploaded_images/3235ecc664ddae45530b60f0c80e91ba.png)

Figure 1: Stereographic projection of C60 fullerene[1]. (Note: To visualize the 3D image, the picture must be held about 15 cm from the eyes and the eyes must focus at infinity).

Figure 2: The C60 molecule showing single bonds (a5) and double bonds (a6) [2].

In the 1980s gas-phase studies, in which clusters and molecular species were produced by laser vaporization of a graphite target, mass spectroscopy was used as the main characterization tool for fullerenes. As might be expected, C60 fullerene was discovered in 1985 by Robert Curl, Harold Kroto, and Richard Smalley using laser evaporation of graphite. Hence, the closed cage nearly sphere shaped C60 fullerene have attracted a great interest in last decades due to its unique structure and properties.

Properties

Theoretically every material exhibits wave-particle ductility behavior, however the buckminsterfullerene (C60 fullerene) is the largest material that is observed to exhibit this behavior. The appearance of fullerenes differs according to the thickness of the material, whether or not they are in solution, and the nature of the solvent. Very thin films of C60 fullerene are mustard yellow, the color becoming brown, and finally black as the film thickness increases. Solutions of C60 fullerene have a beautiful magenta color in hydrocarbon solvents, but appear brown in some pi-donor solvents, due to probably some charge-transfer interactions.

Click Images to Read More about Fullerenes

Solubility

Accurate determination of solubilities is difficult, partly because saturated solutions are dark and opaque, hence it is not easy to see if all the solid fullerene has dissolved. Also, a curious feature is that the solubility passes through a maximum with increasing temperature. However, there is some evidence that the behavior of C60 fullerene in this respect depends upon whether or not the sample has been baked free of solvent prior to carrying out the temperature/ solubility measurements. This aspect is still under investigation, but it seems possible for example, that clustering (there is evidence that this exists in solution), may differ appreciably for baked- and unbaked samples. The close packing in baked samples could cause clusters to be solvated as such, the clusters then gradually breaking up as the temperature of the solution is raised. The solubilities of C60 fullerene have been determined in studies and the results have been discussed over the years. It has been concluded that it is evident that there is no solvent parameter which universally explains the solubility of C60 fullerene. There does seem to be an increase in solubility with increase in solvent molecular size, but any correlation with electron-donating abilities of the solvent is lacking.

Oxidizing Properties and Toxicity

C60 fullerene is a potent producer of singlet oxygen and therefore precautions should be taken to avoid contact with the skin. However, in this connection it should be noted that whilst a water-soluble fullerene carboxylic acid showed biological activity-toxicity and G-selective DNA cleaving ability (but only under the action of low-level visible light) and that fullerenes are potentially excellent photoinduced electron-transport moieties C60 fullerene has been found not to affect the proliferation of human keratinocytes or human fibroblasts indicating that its accumulation in human cells does not result in acute toxicity. Also, under visible or UV irradiation in the presence of molecular oxygen, alkenes and dienes undergo reaction with singlet oxygen if a trace of fullerene is present to give photo-oxygenation products. There is however a disagreement as to the relative effectiveness of the fullerene, some surveys find the former to be the more efficient catalyst, whilst others find it to be the latter. Because C60 fullerene has a low-lying LUMO, it is readily reduced and can acquire, reversibly, up to six electrons under electrochemical conditions. The potentials at which the electrons are added depends on the extent to which the solvent either donates electrons to the cage or accepts them from it. Therefore, C60 fullerene has good oxidizing properties and may oxidize readily the other materials in which it is contact.

Physical and Thermal Properties

Some useful data for C60 fullerene are the following:

Mean diameter, 6.83 4 outer diameter, 10.18 A; inner diameter, 3.48 A; average C-C distance 1.44 A FCC (face-centered cubic) lattice constant 14.17 A. Mass density, 1.72 g cm-1; molecular density, 1.44 x 1021 cm-3;; thermal conductivity (at 300 K), 0.4 W mK-1; phase transition temperatures, 90 K, 260 K. Binding energy per atom, 7.4 eV; electron affinity, 2.65 eV, 1st ionization potential, 7.58 eV; 2nd ionization potential, 11.5 eV; HOMO-LUMO band gap, 1.7 eV.

Production

Three methods are commonly used to make C60 fullerenes. These are:

(i) The Hufmann–Kratschmer procedure involving arc-discharge between

graphite rods in an atmosphere of helium.

(ii) Combustion of benzene in a deficiency of oxygen.

(iii) Condensation of polycyclic aromatic hydrocarbons through pyrolytic

dehydrogenation or dehydrohalogenation

The Hufmann–Kratschmer Method

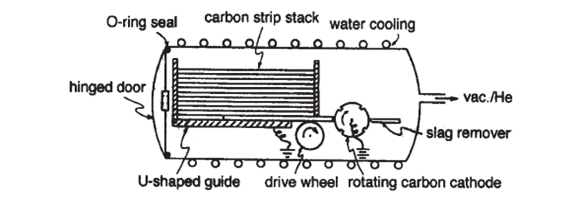

Hufmann-Kratschmer method has been the most important method for fullerene production, and its introduction marked the real beginning of fullerene science. It is the preferred method because the only by-product is graphite, which if necessary, can be reformed into rods and recycled. The Hufmann–Kratschmer method involves arc-discharge between high-purity carbons rods of 6 mm diameter in an atmosphere of 100–200 torr helium. Argon may also be used but is less effective. The temperature required for fullerene formation is 2000 ℃, and obviously a small gap between the rods is necessary to prevent a fall in temperature. The need for this gap was shown at an early stage and was confirmed subsequently. The yield of fullerenes in the soot produced is approximately 5% and is higher when taken from the reactor at greater distances from the arc source, which implies that the initially formed fullerenes are subsequently degraded by UV irradiation. Numerous ingenious variations in reactor design were introduced at an early stage, including, for example, a carousel and one with an autoloading device. The latter method, designed by Bezmelnitsyn and Eletskii is especially notable, using carbon strips cut from a reactor moderator block. A stack of 24 of these (anode) are housed in a water-cooled chamber equipped with a hinged door fitted with an O-ring seal. The cathode consists of slowly rotating a carbon wheel which passes a scraper to remove accumulated slag. The strips are gravity fed and the lowest strip is slowly wheel-driven into the cathode. When consumed it drops away exposing the next strip, and the process continues during 24 hours to yield 100–200 g of fullerene-containing soot, accessed by opening the end door of the reactor.

Figure 3: Schematic depiction of an autoloading version of an arc-discharge apparatus

used for C60 fullerene production[3].

The Combustion Process

Scientists have discovered that combustion of benzene in a deficiency of oxygen resulted in the formation of C60 fullerenes. This continuous method has been developed to the extent that a purpose-built factory has been erected in Japan, capable of producing 5000 ton of fullerenes per year, but currently running at about one-tenth of that capacity. Hence, one envisages that this investment must be driven by the expectation or knowledge that large-scale applications of fullerene lie ahead.

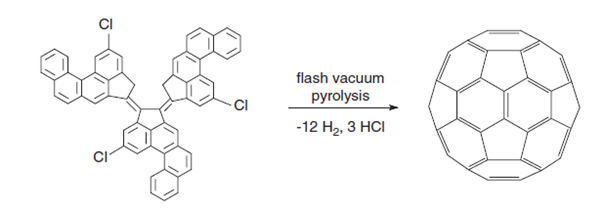

Condensation of Polycyclic Aromatic Hydrocarbons through Pyrolytic Dehydrogenation or Dehydrohalogenation

These methods produce fullerenes but not in sufficient quantities for practical applications. Rather, they provide a means of deducing the mechanisms of fullerene synthesis. For example, C60 consists of six dehydronaphthalene moieties located at the octahedral sites, and pyrolysis of naphthalene does indeed produce C60,7 as does corannulene, (which has been detected as a precursor in the combustion process), 7,10-bis(2,20 dibromovinyl)fluoranthene, and 11,12- benzofluoranthene. The dehydrogenation involved is a high-energy process and dehydrohalogenation of precursors is more successful, a feature made use of in formation of C60 from a chloroaromatic precursor. No other fullerene has yet been made in this way.

Figure 4: Formation of C60 fullerene through dehydrogenation/dehydrochlorination[4].

Applications

Although research on solid C60 fullerene is still at an early stage, these materials are already beginning to show many exceptional properties, some of which may lead to practical applications. Small-scale applications will come first; then targeted applications utilizing the special properties of fullerenes are expected to follow.

Optical Applications

- Optical Limiters

- Photoexcited C60-Polymer Composites

Electrical Applications

- C60 Transistors

- C60 Based Heterojunction Diodes

- C60 Polymer Composite Heterojunction Rectifying Diodes

- C60 Polymer Composite Heterojunction Photovoltaic Devices

- Photoresists

- Silicon Wafer Bonding

- Photolithography

Electrochemical Applications

- Hydrogen Storage and Primary Batteries

- Electrodes for Secondary Batteries

REFERENCES

1.E.W. Godly and R. Taylor, Pure Appl. Chem., 1997, 69, 1411; (b) E.W. Godly and R. Taylor, Fullerene Science and Technology, 1997, 5, 1667.

2.P.W. Fowler and D.E. Manolopoulos, Atlas of Fullerenes, Clarendon Press, Oxford, 1995.

3.L.D. Lamb, in The Chemistry of Fullerenes, R. Taylor (ed), World Scientific, Singapore, 1995, 20–30.

4.Hirsch, The Chemistry of the Fullerenes, Thieme, Stuttgart, 1994; F. Diederich, L. Isaacs and D. Philp, Chem. Soc. Rev., 1994, 23, 243; R. Taylor, The Chemistry of Fullerenes, World Scientific, Singapore, 1995; M.Prato, J. Mater. Chem., 1997, 7, 1097.

5.M.s. Dresselhaus-G. Dresselhaus-P.c. Eklund,Science of Fullerenes and Carbon Nanotubes, 1996.

REFERENCES FOR IMAGES

1.M.s. Dresselhaus-G. Dresselhaus-P.c. Eklund,Science of Fullerenes and Carbon Nanotubes, 1996.

2.M.s. Dresselhaus-G. Dresselhaus-P.c. Eklund,Science of Fullerenes and Carbon Nanotubes, 1996.

3.M.s. Dresselhaus-G. Dresselhaus-P.c. Eklund,Science of Fullerenes and Carbon Nanotubes, 1996.

4.M.s. Dresselhaus-G. Dresselhaus-P.c. Eklund,Science of Fullerenes and Carbon Nanotubes, 1996.

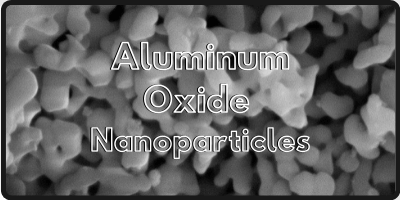

Silicon Carbide (SiC) Micron and Nano Powder

Silicon carbide nanoparticles have wide applications in field emission displays and light emitting devices. Moreover, nanoscale silicon carbide is used in designing and manufacturing electro-devices in nanoscale, nanosensors and biological labels. Bulky silicon carbide (SiC) is known as a refractory agent and semiconductor with excellent thermal, mechanical and chemical behavior. The melting point of this non-oxide ceramic is above 2800 °C, perfectly resistant against corrosion with low thermal expansion coefficient. Silicon carbide has a large bandgap and remarkable mechanical strength with low density and high hardness 1.

Silicon Carbide Properties

Silicon carbide, also known as carborundum, has a rare natural occurrence found in moissanite mineral. However, it has been largely produced as powder since the late nineteenth century with the most application as an abrasive agent. It been found applications in semiconducting electronics devices which function at high voltages and high temperatures. The most favorable electronic properties of silicon carbide include low quantum confinement, high ionic mobility, high breakdown electric field, and high saturation electron drift velocity and high thermal and electrical conductivity. Using a technique called Lely method, silicon carbide’s large single crystals are grown and cut as small as gems called synthetic moissanite. Through binding silicon carbide together, practically hard ceramics are used as a highly enduring agent in car clutch and ceramic plates, car brakes and bulletproof vests. Silicon carbide is also used in electronics, in designing detectors and light emitting diodes (LEDs). Even though silicon carbide is rarely found on Earth crust, it is highly abundant in space mostly near carbon-rich stars with the most common crystal forms as beta-polymorph. In general, crystalline silicon carbide comprises some 250 different forms and is produced in glassy amorphous crystals by pyrolysis of preceramic polymers in an inert gas atmosphere. The most common crystalline structure of SiC is alpha silicon carbide (α-SiC) with a hexagonal configuration which forms at temperatures over 1700˚C. There is a modified silicon carbide as β-SiC which is processed using a zinc blend crystal structure with applications in supports for heterogenous catalysts due to their higher surface area compared to the alpha form.

Read More About Silicon Carbide (SiC)

Silicon Micron and Nanoparticles powder

Particles and mostly crystals can be classified according to their size as nano and micron. Generally, the particles with their size around 70 microns are referred as micron particles while those with sizes below 100nm are considered as nanoparticles. Silicon carbide (Sic) is available as micron and nano scales with different properties as well. Regarding high fracture toughness, excellent hardness, high resistance towards oxidization, perfect mechanical strength and stability in extreme environmental conditions, silicon carbide is expected to adopt novel and even improved properties when its obtained in nano scale. The silicon nanoparticles have been demonstrated to exhibit new properties in addition to the improved behaviors mentioned earlier. Silicon nanoparticles have unique optical and electrical properties with higher strength and hardness when included in some target materials. Technically, the impact of silicon carbide nanoparticles has been investigated so precisely proving remarkable impact of the size their physical and mechanical behavior. It has been shown that the encapsulation of smaller silicon carbide nanoparticles in the bulk of aluminum has resulted in significant grain refinement when compared to SiC nanoparticle with bigger sizes. Moreover, the particle mean size has been demonstrated to influence the heat transfer capability and basic microscopic properties of α-SiC/water nanofluids. It has been proved that large-particle nanofluids have lower viscosity and higher thermal conductivity which is originated from the solid/liquid smaller area of interface. What’s more, the particle size directly and significantly affects the catalytic activity 2.

Synthesis and Preparation of Silicon Nano/Micron Particles and Powder

Numerous synthesis methods with different particle size based on the application has been reported in the literature. The methods introduced so far, have achieved particles in micron and nano size scales. However, the synthesis methods with nanoscale silicon carbides are mostly favorable. According to a method, silicon nanoparticles are prepared through using the wastes of compact discs (CDs) char as the carbon source silicon oxide for silicon and following the carbothermal reduction procedure at 1550˚C. the carbon from the CD wastes is extracted through pyrolysis technique in argon atmosphere at 700˚C for about 20 minutes. Silicon dioxide (SiO2) and the carbon extract are mixed based stochiometric ratio in a ring mill for a period of two hours to gain pellets. The pellets are put in a furnace to process the carbothermal reduction for an hour to finally obtain the silicon nanoparticles with the sizes ranging from 40 to 90 nm 1. Based on a report using the so-called sol-gel method, silicon carbide nanoparticles are synthesized using the tetraethyl orthosilicate (TEOS) as the precursor with hydrochloric acid and ethanol to control the pH and homogeneity of the reaction solution. According to this method, particle size shows to have increased the density and harness of resulting nanoparticles 3. In a technique, silicon carbide nanowires are prepared taking the advantage of metal catalyst free thermal evaporation technique. The process involves the placing silicon and graphite aside in a columnar graphite crucible with the entire system inside a vacuum furnace and argon gas atmosphere and heating it up to 1000C 4.

Applications of Silicon Nano/Micron Particles and Powder

Considering the mechanical strength, harness and thermal properties of silicon carbide with the improved quality in its nanoscale, silicon carbide nanoparticles have found applications in numerous sectors of industry. Silicon nanoparticles are famous for their practically wide bandgap in electronics and have been applied there. Another property that has made SiC nanoparticles so common and popular is their thermal conductivity. Also, in extreme environmental conditions, the use of a material with higher thermal conductivity seems essential. All the mentioned properties and specifications have led to silicon nano and micron particles application in electronic devices, field electron emission, sensors and power electronics. They are used as blue and ultra violet emitting diodes since they are capable of emitting sable and high-intensity blue and green light as well as ultra violet radiation. Silicon nano and micron particles have tuned out as effective and economical materials for industrial and engineering uses namely nanodevices, microelectronics, in biomedical engineering devices, nanocomposites, hydrophobic, and optoelectronics mainly due to the fact that SiC nanoparticles don’t need cooling down.

Click Image to Learn Also About Silicon

SiC carbides carbide nano and micron particles and powder show much improved and intensified properties compared to their bulky form. It has been shown that many properties of bulky silicon carbide are directly dependent on the particles size like the bandgap, as an example, has different widths when it is in bulky, micron and nano scales. SiC in its all particle size range show promising hardness, toughness with excellent mechanical strength.

References

1. Rajarao, R., Ferreira, R., Sadi, S. H. F., Khanna, R. & Sahajwalla, V. Synthesis of silicon carbide nanoparticles by using electronic waste as a carbon source. Mater. Lett. 120, 65–68 (2014).

2. Sun, B., Xie, R., Yu, C., Li, C. & Xu, H. Structural characterization of SiC nanoparticles. J. Semicond. 38, (2017).

3. Birru, A. K., Reddy, G. K., Ajay, G. & Kumar, N. K. Effect of Reinforced Silicon Carbide Nanoparticles in Epoxy Composites. Mater. Today Proc. 2, 4348–4352 (2015).

4. Mohd Sohor, M. A. H., Mustapha, M. & Chandra Kurnia, J. Silicon carbide- from synthesis to application: A review. MATEC Web Conf. 131, 1–6 (2017).

Molybdenum Oxide Nanoparticles

Nowadays, oxidation reactions play a substantial role in modern chemistry as well as chemical industry. Around 30% of total production in the chemical industry is carried out by the oxidation process. It means that after polymerization, oxidation is the largest process in the production of chemicals.

In the last few decades, transition metal oxides have attracted the research community in great deal due to their diversified applications. Among them, molybdenum oxide has been found to be one of the most fascinating materials due to its unique structural, optical, electrical, and mechanical properties and multidirectional applications such as gas sensing, photocatalysis, field emission (FE), capacitors, resistive switching, solar cells, light emitting diodes, hole transport materials, etc. Molybdenum is a Block D, Period 5 element, while oxygen is a Block P, Period 2 element in the periodic table. Molybdenum does not occur naturally as a free metal on EarthMolybdenum oxide is a wide bandgap material whose bandgap varies from insulating MoO3 (≈3.2 eV) to more conducting MoO3-x to semi-metallic MoO2 (≈2.55 eV). Molybdenum oxide exists in several phases such as MoO3 (orthorhombic, monoclinic, and hexagonal), Mo4O11 (monoclinic and orthorhombic), Mo5O14 (tetragonal), Mo8O23 (monoclinic), Mo9O26 (monoclinic), and MoO2 (monoclinic) depending upon the oxygen concentration and the oxidation state (+6, +5, +4, and +2) of Mo. The commonly used molybdenum oxide, MoO3, have three different polymorphs and these are:

i) a thermodynamically most stable orthorhombic structure(α-MoO3)

ii) a metastable monoclinic structure (β-MoO3) and

iii) a metastable hexagonal structure (h-MoO3).

Molybdenum oxide nanoparticle, also known as molybdenum trioxide nanoparticle, is a fine light blue powder composed primarily of MoO3 particles with diameters of 100nm or less generally.

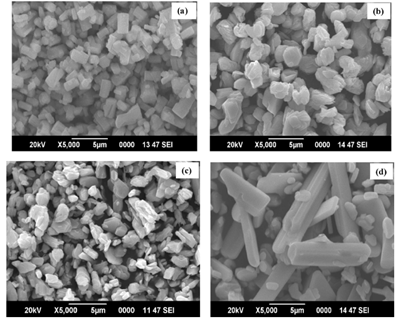

Figure 1: SEM image of MoO3 nanoparticles at different annealing temperatures (a) as-prepared, (b) 400 °C, (c) 500 °C and (d) 600 °C [1].

Due to high melting point, high chemical and thermal stability, and metallic conductivity, monoclinic MoO2 has attracted much attention in the research community.Looking to its high chemical stability, quick oxidation-reduction process, easy nanometric sized particles preparation procedure, we selected molybdenum oxides as viable candidates. Mo exists in three oxidation states and thus can readily participate in redox reactions and exhibits interesting metallic electrical conductivity. Hence, the nanostructured molybdenum oxide particles (MoOx NPs) could act as efficient electron redox mediators, contributing to the electrochemical sensing of some biological compounds such as dopamine. MoOx NPs are widely used in lithium ion batteries, capacitors and gas sensors, while their application in bio-sensing is still limited. Different types of MoO2 morphologies such as nanoparticles, hollow spheres, sheets, large scale nanowires, and nano stars have been synthesized via diversified techniques such as hydrothermal reaction, thermal evaporation, solution-based reactions, and hydrogenation processes. Molybdenum dioxide is also an unusual transition metal oxide because of its high metallic-like electrical conductivity, which is associated with its mixed interatomic bonding and a relatively high density of states at the Fermi level. The existence of free electrons in this region enhances the catalytic activity of Mo4+ in MoO2, unlike that of Mo6+ in MoO3, where all the valence electrons of the metal are covalently bonded to neighboring oxygen atoms. The metallic conductivity of MoO2 makes it a material of interest for many applications, including catalysis. Most recently it has been studied as a possible anode for lithium-ion batteries.

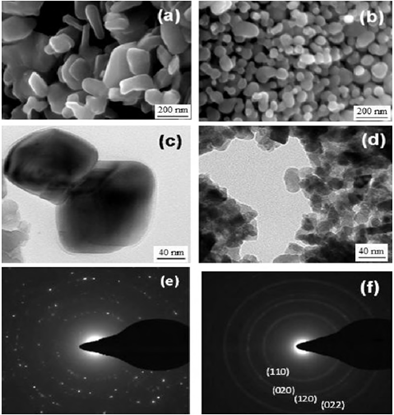

Figure 2: SEM and TEM images of commercially available MoO2 (a and c) and nanoparticle MoO2 (b and d). The corresponding selected area electron diffraction patterns asshown in (e) and (f), respectively. The index of electron diffraction pattern for nanoparticle MoO2 (f) matches to that of pure bulk MoO2[2].

Different morphologies of MoO3 nanostructures (NSs) such as nanoribbons, nanobelts, nanorods, nanowires, nanotubes, and nanosheets are prepared by various physical and chemical methods. Different techniques are deployed to synthesize MoO3 NSs successfully such as chemical vapor deposition (CVD), thermal evaporation, e-beam evaporation, pulsed laser deposition, sputtering, hydrothermal, molecular beam epitaxy (MBE), and van der Waals epitaxy.

MoO3 is a promising candidate to realize applications in electronic, photo-catalytic, gas sensor, biological activity, electrochromic, photochromic, lithium-ion batteries etc., owing to its tunable properties. It is an n-type wide bandgap semiconductor with three crystal structures (i) orthorhombic (α-MoO3) which is thermodynamically stable, (ii) metastable hexagonal (h-MoO3) and (iii) monoclinic (m-MoO3). Orthorhombic (α-MoO3) phase is widely studied by researchers because it gives out many applications. Molybdenum oxide nanoparticles can be synthesized through various methods like hydrothermal, microwave irradiation, co-precipitation, sono-chemical, flame synthesis, sol-gel etc. Among these methods, co-precipitation is a simple and cost-effective method capable producing large quantity of yield. There are many influencing synthesis parameters like acid or base, PH, surfactant, source material, annealing temperature etc., which could change the property of the bulk material significantly.

Laser Ablation of Solids in Liquids

The so-called LASL technique is an effective method to obtain nanostructures. This method is promising since the NPs formed can be free of both surfactants and other ions that exist during chemical synthesis, and it differs from laser ablation in vacuum or gaseous environments since the liquid can help to control some of the parameters of fabrication and to obtain the desired morphology and microstructure. In the LASL process, material is removed from the surface of a target in the form of plasma by the application of a high pulsed laser beam. Usually a target is submerged in a liquid and the laser is focused on the target through the transparent medium. When using the LASL method with metals, there are two main formation mechanisms proposed for the generation of nanostructures:

i) The thermal evaporation with liquid interaction, and

ii) The explosive ejection of nanodroplets. In the former, the formation of nanostructures is associated with the combination of ultrafast quenching of hot plasma and its interaction with surrounding media

In the latter case, it is suggested that the laser irradiation could cause a local melting from the metal target, the adjacent liquid layer is heated to vapor or plasma state with a high pressure, which splashes the molten target into nanodroplets that react with the liquid medium and create the final nanostructures.

Click Image to Learn Also About Molybdenum Sputtering Targets

Reduction of Molybdenum Trioxide Powder

Nanoparticle MoO2 is synthesized by reduction of molybdenum trioxide (MoO3) powder in a 1:3 volume ratio of ethylene glycol to distilled water. The mixture is combined in a Teflon-lined general-purpose vessel, which is subsequently sealed and heated to 180℃ for 12 hours. The liquid ratio of 1:3 was chosen because it yields pure single phase MoO2, without the need for any post-synthesis reduction. After cooling, the dark colored MoO2 was filtered and air dried at 100℃. It is relevant to note that the process used to produce the MoO2 nanoparticles is scalable and large quantities of catalyst could easily be prepared.

Applications

For molybdenum oxide nanoparticles, there are various types of applications. The key applications of molybdenum oxide nanoparticles are as follows:

- In electrochemical capacitors

- In coatings, nanowires, nanofibers, plastics, and textiles

- In specific alloy and catalyst applications

- As catalysts, oxidation catalysts, cracking catalysts, hydrogenation catalysts, and pigments

- In ceramics and glass production

- As a raw material for the production of molybdenum metal.

Catalyst applications: Like many nanomaterials, molybdenum oxide has several applications as a catalyst and is the subject of substantial research. Current known uses include hydrogenation catalysis and cracking catalysis.

Electrochemical applications: The unique electrical and chemical traits of molybdenum oxide at nanometer scales makes it of particular interest in the production of various displays and electrochemical devices.

Material production applications; Probably the primary current usage of molybdenum oxide lay in its versatility in the production of different materials. It serves as a seed material for producing various related substances, such as molybdenum metal, and is used as an additive and ingredient in various glasses, ceramics, and other compound materials.

Pigment applications: The unique optical properties of molybdenum oxide make it of occasional use as an additive for pigmentation.

REFERENCES

1.G. Pradeesh, V. Ponnuswamy, B. Gowtham, R. Suresh, J. Chandrasekaran, Influence of annealing temperature on the properties of molybdenum oxide nanoparticles prepared through chemicalprecipitation method for p-n junction diode application, Optics, 6 September 2018.

2.S. Muthamizh, R. Suresh, K. Giribabu, R. Manigandan, S. Praveen Kumar, S. Munusamy, A. Stephen, and V.Narayanan, Molybdenum oxide Nanotubes: Synthesis and characterizations, https://doi.org/10.1063/1.4917796 Published Online: 25 June 2015

3.J. Appl. Phys. 127, 025301 (2020); https://doi.org/10.1063/1.5127227 Submitted: 12 September 2019. Accepted: 21 December 2019. Published Online: 08 January 2020

4.G. Pradeesh, V. Ponnuswamy⁎, B. Gowtham, R. Suresh, J. Chandrasekaran, Influence of annealing temperature on the properties ofmolybdenum oxide nanoparticles prepared through chemical precipitation method for p-n junction diode application, Optics, 6 September 2018.

5.Le Xin Song, Mang Wang, Shu Zhen Pan, Jun Yang, Jie Chen and Jing Yang, Molybdenum oxide nanoparticles: preparation, characterization, and application in heterogeneous catalysis, Journal of Materials Chemistry, 24 March 2011.ssss

REFERENCES FOR IMAGES

1.G. Pradeesh, V. Ponnuswamy, B. Gowtham, R. Suresh, J. Chandrasekaran, Influence of annealing temperature on the properties of molybdenum oxide nanoparticles prepared through chemicalprecipitation method for p-n junction diode application, Optics, 6 September 2018.

2.Oscar Marin-Floresa, Timothy Turbab, Caleb Ellefsonb, Kang Wangb, Joe Breit c, Jeongmin Ahnb, M. Grant Nortonb, Su Haa, Nanoparticle molybdenum dioxide: A highly active catalyst for partial oxidation of aviation fuels, 2 June 2010.

Indium Tin Oxide

Indium Tin Oxide is a mixture of indium and tin. The typical composition by weight is 90% In2O3 and 10% SnO2. It is, therefore, indium oxide where a small fraction of indium atoms is replaced by tin atoms: we can say that it is indium oxide doped with tin. We will discuss all about it in this article.

Metals are of great importance in all areas of society, among them, Indium and Tin also stand out. Indium Tin Oxide has huge significance due to its unique properties which open the door for unlimited applications.

Let’s first find out about Indium and Tin individually:

Indium

The indium is an element of the periodic table. Its atomic number is 49 and its chemical symbol is In and its atomic weight is 114.82. It is relatively little abundant in the earth’s crust: approximately 0.000016% of the total materials in it correspond to this metal, which is equivalent to that for every kilogram of crust there are 0.25 milligrams of indium. Moreover, there are no known deposits where it exists in elemental form or in great concentration in any of its compounds; rather it is spread among other minerals. Therefore, the Indium obtained from the subsoil is a byproduct of the extraction of lead and zinc. Although in our times, the mining production of indium is lower in volume as compared to recycling products that contain it.

The Indium is so soft that it can be scratched with the nail. In its pure state, it is a soft and malleable material, silver in appearance; its density at 20 °C is 7.31 g/cm3. It even leaves a trace when rubbed on paper, as if it were a pencil. Its hardness is of value 1.2 on the Moh’s scale. In this gradation, the talc is assigned 0, while the diamond corresponds to 10; the wax has a hardness of 0.2, while 2.5 is the value for the material that forms our nails.

Indium is a metal that conducts electricity better than iron. Its electrical conductivity is of the order of 18% of the value corresponding to silver. Its boiling point is 2072 ° C and its melting point is 156.5985 °C. This value serves as one of the 14 calibration points of the international temperature scale (ITS-90). Also, due to its relatively accessible melting point, this material serves as a reference in the calibration of differential scanning calorimetry instruments.

Since an atom of indium has 49 electrons, its electronic configuration ends at level 5: 5s2 5p1. For this arrangement of electrons, its oxidation state is generally +3, although less often it usually has a +1 state. In the first state, it can form compounds with halogens such as InCl3, with oxygen (In2O3) and with sulfur (In2S3); the last two molecules only form at high temperatures. In the +1 state, it can form compounds such as InCl, InBr or In2O.

Now let’s find out about Tin:

Tin

Tin is known since ancient times and it was used mainly for the manufacture of weapons in times of war. Tin is a relatively rare element since it is not found in abundance on the planet. Its uses began around 3500 BC in the city of Ur, located in southern Mesopotamia, now known as Iraq. It began to be used in alloys with copper since when mixing copper and tin, they noticed a new metal they called bronze. This new material was resistant to corrosion due to the properties that tin grants to copper. During the development of this new material, an intense trade arose over long distances to obtain tin. The bronze turned out to be more efficient than the materials used at the time, Like rocks and bone. Today it is used to coat metals applied to food lateries, soft welding, label production, fungicides, pigments, dyes, among other applications.

Tin can be obtained from the mineral cassiterite or tin IV, being the most common mineral phase. It is obtained by reduction with coal. On the other hand, tin has taken great relevance when presented as a metal oxide, such as tin oxide (tin IV), because when mixed with the oxygen molecule, it can be used in applications such as chargers for lithium batteries, solar cells, optoelectronic devices, gas sensors, among others, where it encompasses electronic, optical and catalytic applications.

The SnO2 has a prohibited band of 3.6 eV and electronic mobility of 100 to 200 cm2 V-1 s-1. These values help us understand the ability of the material to apply in optoelectronics. It is considered an interesting material compared to other metal oxides due to its excellent stability, low cost, and its various applications.

Indium Tin Oxide Nanoparticles

Indium Tin Oxide Nanoparticles are of even greater importance in their nano size. It has a high transmittance, that is, it lets a high amount of energy pass to a medium. In addition to being transparent, it also has a low electrical resistivity, so it easily allows the movement of electric charge. All this occurs between visible and infrared radiation.

It is a highly degenerate n-type semiconductor (electrical conduction takes place by electrons). This material is weakly electronic conductor but remains transparent to visible light provided that it is in the form of a thin layer. This oxide is a better conductor of electricity than other transparent oxides like ZnO etc. The increase in electrical conductivity by doping leads to an increase in the absorption of light and the ITO layer turns yellow.

Indium Tin Oxide films on glass plates are obtained by different deposition techniques and generally by spraying (PVD for example).

Click Image to Read Also About Zinc Oxide

Applications of Indium Tin Oxide

1.Indium Tin Oxidefilms are mainly used as transparent electrodes for flat screen displays, touch screens, solar cells, organic light-emitting diodes (LEDs), certain anti-static coatings and screens against electromagnetic radiation but transparent to visible light. The development of electrochromic glazing is made possible thanks to this type of transparent electrodes deposited on glass. This type of deposit can also be used as a deicing system. Sheets of glass coated with transparent ITO films which conduct electricity are sold.

2.The most commonly used material for manufacturing conductive and transparent materials is tin and indium oxide.

3.The use of transparent conductive films from ITO is proposed as a new complete front electrode to replace conventional metal lines in the third generation group III-V solar cells.

4.The films were deposited by the DC-Magnetron Sputtering technique at room temperature and were optically, electrically and structurally characterized. Sample thicknesses were obtained by means of fixed wavelength ellipsometry. The crystalline structure of the deposited films was determined by x-ray diffraction, the diffractograms show the characteristic peaks of the typical bixite structure.

5.ITO films are used in cold regions and doors or walls of advanced buildings so that the heat stored in certain enclosed spaces. It plays a role in the thermal shield, and for the outside world, it is difficult to radiate heat to the room, due to which energy consumption in construction, heating, air conditioning, and lighting is reduced by more than 50%.

6.ITO thin film has an index of refraction and electrical conductivity, so it is suitable for a silicon solar cell and a collection of gross light antire reflector coating. Because it has a selective light-transmitting infrared light and reflectivity to visible light, the use of light-heat conversion and the effective use of solar heat can be made as to the permeable membrane, effectively trapping heat in the collecting reactor.

7.ITO is also used as a transparent film, a conductive function, such as an automobile coated glass, windshield machine, aircraft, and spacecraft laser porthole tank rangefinder.

8.This material is used to make transparent electrodes in display devices with flat screens (for example LCD screens) and electrochromic glazing.

9.Other uses include gas detectors, electro-moistening in dielectrics, and Bragg reflectors for vertical-cavity laser diodes emitting from the surface.

So, overall Indium Tin Oxide is used in the

- Preparation of sensitive surfaces

- Construction of lighting fixtures.

- Construction of electrical, electromagnetic and electronic apparatus and instruments.

- Construction of telephone, telegraphic, receiver-transmitter, electronic calculators.

- Construction of electrical systems.

- Construction of measuring and control instruments.

- Construction of cathode ray tubes, light bulbs, vacuum tubes or gas tubes.

- The inorganic and organic chemicals industry.

Smart Windows

Smart windows have a glass that selectively absorbs visible light when a voltage is applied, changing its degree of transparency to light and outside heat. These smart windows allow reducing the energy demand of a building (in lighting and air conditioning). Several professors from Univ of California in Berkeley published in Nature a new electrochromic material composed of indium and tin oxide (ITO) nanocrystals embedded in a glass of niobium oxide. One of the most interesting advantages of the new material is that it allows separate control of the light absorption in the visible and near-infrared, that is, in a smart window, optical and thermal transparency can be controlled separately and independently.

The performance of the new material is much better than expected, although there are some technical issues to be resolved before this new material can be used in windows in our homes (better electrode materials must be selected and it is convenient to use a solid electrolyte instead of liquid). Even so, it is a very promising job.

Researchers have developed a new synthesis technique to embed the nanoparticles in the glass. Indium and tin oxide (ITO) nanocrystals are coated with polyoxomethalates (POM), clusters of metal cations and oxo anions joined by covalent bonds to the surface of the ITO. These nanocrystals condense and form a film, which receives a heat treatment (heated to about 400 °C), and then densely packed in a niobium oxide (NbO) inside the glass matrix. Without going into technical details, this method provides a rigorous control of the size and spatial distribution of the nanocrystals in the glass. The latter is very important because the structural order of the nanocrystals greatly improves the properties electrochromic glass matrix.

Thus, Indium Tin Oxide is an important compound mainly used to make transparent and conductive coatings at the same time for screens. It is used in the making of liquid crystals, flat screens, plasma screens, touch screens, electronic ink applications, organic diodes, light-emitting diodes, photovoltaic cells, antistatic coatings, electromagnetic interference shields and much more.

References

https://www.researchgate.net/publication/322539063…

https://iopscience.iop.org/article/10.1088/1742-65…

https://aip.scitation.org/doi/10.1063/1.370948

https://www.researchgate.net/publication/234922459…

Lead Zirconate Titanate (PZT) Nanopowder

Lead zirconate titanate (PZT) and its nanoscale crystals are known as the most common ferroelectric inorganic compounds employed as piezoelectric materials with the highest coupling coefficient between its mechanical and electrical properties. Lead zirconate and titanate appears to have a morphotropic phase boundary at molar ratio fraction ranging from 0.4 to 0.6 supporting its sample processing setting and compositional homogeneity 1. The morphotropic phase boundary is a point where the Ti:Zr ratio is 48:52 at room temperature adequate to achieve the best piezoelectric properties. Lead zirconate titanateis originally a solution containing antiferroelectric PbZrO3 and ferroelectric PbTiO3 with their Currie temperatures as 230°C and 490°C, respectively 2. Generally, lead zirconate titanate shows better sensitivity at higher operation temperatures. Regarding these properties and chemical inertness and physical strength with relatively low preparation cost, lead zirconate titanate is among the most common piezoelectric materials in the industry.

Properties of Lead Zirconate Titanate Nanoparticles

Lead zirconate titanate nanoparticles properties are directly influenced by the doping sintered density and the structure of the materials based on PZT. Technically, the sintered density and structure depend critically on the process through which they are synthesized and the reagents used in for the synthesis. Considering the numerous studies concerning the piezoelectric, dielectric and optical properties of nanosized ferroelectric materials that have perovskite structure have drawn increasing attention. It is evident that materials in the nanoscale possess higher surface area to volume ratio compared to particles in micron and bigger scales and as a result, exhibit incredible and new chemical, physical, mechanical, optical and electrical characteristics. In this context, the lead zirconate titanate (PZT) nanoparticles Pb(ZrxTi1x)O3 are the subject of many studies because of their pyroelectric, dielectric energy storage capabilities, piezoelectric, electrochemical and electro-caloric effects, mechanical and electrical properties. In the case of lead zirconate titanate nanoparticles the best properties mentioned above are observed for compositions with their morphotropic phase boundary at near 0.5 3. In general, PZT nanoparticles and nanopowder (with relative permittivity between 300 to 20000) are in a wide range of frequencies with quick response time when used in detectors and could be applied in circuits with low or high voltages possessing good mechanical and acoustic coupling.

As a piezoelectric material, PZT adopts a potential difference under changing temperature conditions across its surface which physically changes shape when it is exposed to an external electrical field. PZT has a spontaneous electric polarization or electric dipole to be reserved in an electric field owing to its ferroelectric property. PZT is commercially not used alone and pure but is doped with either donor agents creating cationic vacancies as well as facilitating the domain wall motion in it or with acceptors creating anionic vacancies. The point is the acceptor doping results in harder PZT, whereas the donor doping causes softer crystals. Particularly, soft and hard lead zirconate titanate are different in their piezoelectric constant with the soft PZT crystals having a higher piezoelectric constant and the hard one with the lower piezoelectric constant. The reason the piezoelectric constant is proportional to the electrical field that is generated per unit of mechanical stress and polarization as well as the mechanical strain caused by the applied electric field.

Synthesis and Preparation of Lead Zirconate Titanate Nanoparticles

The significant roles that lead zirconate titanate nanoparticles have among the ferroelectric materials require the need for the best and most efficient methods with lowest expenses to obtain them in both in industrial and batch scales. Regarding this several synthesis methods have shown to possess enough quality to be applied for the PZT nanoparticles production. These methods and techniques involve co-precipitation, hydroxide co-precipitation, sol-gel combustion, hydrothermal, electro hydrodynamic atomization focused ion beam, microwave hydrothermal and electro-hydrodynamic atomization. In the sol-gel method, pure and homogenous PZT nanoscale particles are synthesized. The sol-gel preparation method takes place in a liquid solution of metal organic precursor leading to the formation of separate phase through the hydrolysis and condensation.

The main reagents to obtain ferroelectric lead zirconate titanate are Zr(OR)x, Ti(OR)x alkoxides and lead acetate Pb(OAc)2.3H2O which are made to react based on the sol-gel method. In so doing, a hetero-metallic alkoxide solution is prepared through mixing Pb, Zr and Ti and then stabilized by acetyl acetone. After the solution is prepared, an acidic or basic hydrolyzing agent is added to the solution to affect the pore structure and the stoichiometry of the gel. In this sol-gel method which takes the advantage of acetate-alkoxide, the amount of acetic acid as the solvent directly affects the particle size of lead zirconate titanate crystals, their homogeneity and stoichiometry 4. In a different method, lead zirconate titanate nanocrystals are synthesized using the citrate nitrate auto-combustion with the particle size ranging from 10 to 15 nm 2. One different sol-gel method of lead zirconate titanate nanoparticles preparation involves the synthesis at different pH values. Accordingly, the pH appear to affect transverse optical (TO) phonon modes, LO-TO splitting, the longitudinal optical (LO), extinction coefficient k(x) and refractive index n(x) 3.

Applications of Lead Zirconate Titanate Nanoparticles

The number research projects and publications submitted on the synthesis of PZT nanoparticles proves how capable and practical the nanoscale lead zirconate titanate are in science and industry. Therefore, the applications of PZT are broadly presented in the literature. The application of PZT nanoparticles originally arises from their piezoelectric and ferroelectric nature. They are employed in high temperature applications with truly high sensitivity in various sensors and actuators. Thin films of PZT are used in electronic and optical devices and memory devices. The medical applications of PZT are in ultrasonic transducers used for medical imaging. Moreover, they are used in underwater communication devices, electrical resonators, wave filters, fish finders, speakers and hydrophones. In addition to broad industrial applications, lead zirconate titanate nanoparticles have found optical applications in waveguides due to the PZT optical properties. In this category, the applications of lead zirconate titanate nanoparticles are in infrared (IR) optical field effect transistors, lamb wave devices and modulators. Considering the extensive range of infra-red spectroscopy, PZT nanoparticles are used in sensing, detecting, transmitting and pyroelectric IR detectors.

Lead zirconate titanate nanoparticles and nanopowder are inorganic ferroelectric agents with piezoelectric property and with the applications in piezoelectric resonators, ultrasonic transducers and IR spectroscopy. They are chemically inert and physically strong making PZT nanoparticles one of the most common piezoelectric compounds.

References

1. Garnica-Romo, M. G. et al. Nanoparticles of lead zirconate titanate (PZT) used as ferroelectric ceramics produced by sol–gel acetic-acid route. J. Sol-Gel Sci. Technol. 74, 425–431 (2015).

2. Banerjee, A. & Bose, S. Free-standing lead zirconate titanate nanoparticles: Low-temperature synthesis and densification. Chem. Mater. 16, 5610–5615 (2004).

3. Pakizeh, E. & Moradi, M. Effect of particle size on the optical properties of lead zirconate titanate nanopowders. J. Am. Ceram. Soc. 101, 5335–5345 (2018).

4. Garnica-Romo, M. G. et al. Nanoparticles of lead zirconate titanate (PZT) used as ferroelectric ceramics produced by sol–gel acetic-acid route. J. Sol-Gel Sci. Technol. 74, 425–431 (2015).

Nanomedicine and Nanodrugs

Nanotechnology has found practically extensive range of applications in almost all areas of science, technology and industry due to the surprising behavior, excellent performance and novel properties matter adopts when it falls into nano scale. Medicine has greatly taken advantages of nanotechnology not only in instrumentation but in drug synthesis with so many nanodrugs as well as applications in drug delivery and diagnostics. The findings based on nanoparticles and nanotechnology and the truly promising outcomes have led to an area in science called nanomedicine which specifically focuses on the application of nanotechnology and nanoparticles to promote the efficacy of medication, diagnostics and medicine at whole.

Click Image to Check A Similar Article on Blografi